Grintimate exclusively developed the hydrostatic bearing technology, it can greatly reduce the vibration and wear caused by the metal due to the non-contact characteristics of hydrostatic oil film. The machining accuracy and service life of the product can be improved substantially as well!

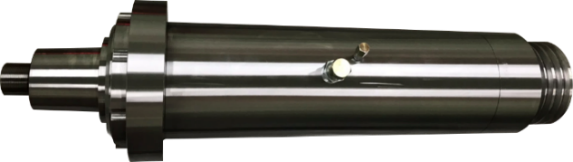

Hydrostatic Bearing Spindle

| Non-friction, low heat & vibration resistance. |

| Advanced hydrostatic lubrication & coolant system and flow control system which enhances the grinding quality, pressure stability and improves the precision of feeding & positioning. |

| Exclusively developed the hydrostatic bearing system, it can minimize the factor of thermal deformation. |

| The high rigidity of hydrostatic spindle both on radial and axial bearing can optimize the surface roughness to reach Ra<0.02µm, heavy grinding efficiency and mirror-surface processing performance. |

| Based on the high rigidity of hydrostatic bearing spindle, the width of grinding wheel is rated up to 300mm. Only one time processing from rough to finishing grinding, greatly improves the grinding efficiency. |

| The high damping characteristics of the hydrostatic bearing system can completely absorb the grinding kinetic energy. |

Hydrostatic Rotary Worktable

| High load capacity > 10,000kg |

| Static rigidity > 400kgf/μm which makes it ideal for heavy cutting. |

| The hydrostatic bearing structural design both radial and axial which supports to eccentric stress & high centrifugal forces processing. |

| Non-friction and rotation accuracy < 1μm. |

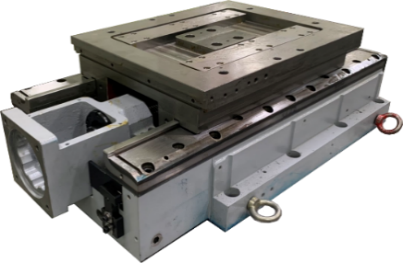

Hydrostatic Guideway

| Non-friction & low wear and high stability supported by hydrostatic oil film. |

| Perfectly for high precision positioning & sub-micron feeding. |

| High load capacity, high damping and high vibration resistance. |

| No stick-slip design, the hydrostatic oil film has an error averaging effect. |

| High loading capacity & prolongs service life twofold of ball screw. |