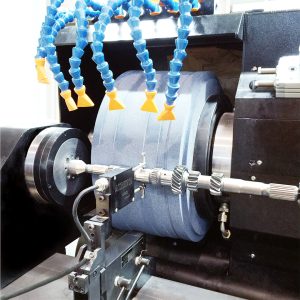

Hydrostatic Cylindrical Forming Grinding Machine-CTS Series

Model number:CTS-100

Characteristics

- Only one-time processing with formed grinding wheel can achieve the required dimension accuracy on each workpiece, the quality is affirmed & the processing efficiency is improved.

- The grinding wheel can be widened to max. 300mm with one-feeding grinding (max. 15-steps) which can completely satisfy customer’s required processing accuracy.

- X axis is equipped with hydrostatic guideway which presents no stick-slip and low friction, perfect for high precision positioning and high loading capacity.

- Headstock and tailstock both work with double-sided synchronous which can avoid the interference between carrier & workpiece during grinding, greatly improve the production efficiency.

- Specialized for high precision grinding of transmission shaft under mass production.

Specification

| MODEL | UNIT | CTS-100 |

| Controller | Fanuc 0i-TF | |

| Capability | ||

| Distance Between Centers | mm | 650 |

| Swing Over Table | mm | 400 |

| Max. Load Held Between Centers | kg | 35 |

| Max. Grinding Diameter | mm | 380 |

| Grinding Wheel | ||

| Size (diameter x width x bore) | mm | Ø455x(50-300)xØ254 |

| Max. Wheel Speed | rpm | 2000 |

| Max. Peripheral Speed | m/sec | 48 |

| Wheelhead | ||

| X axis stroke | mm | 200 |

| Workhead | ||

| Center Taper | -- | MT:4 |

| Spindle Speed | rpm | 20~600 |

| Tailstock | ||

| Center Taper | -- | MT:4 |

| Center Taper Type | -- | Hydraulic |

| Stroke | mm | 25 |

| Fine Adjustment Range | mm | -- |

| Table | ||

| Z axis stroke | mm | 800 |

| Swiveling Angle | deg | -- |

| Capacity | ||

| Hydrostatic Bearing Spindle Tank | liter | 80 |

| Hydraulic Tank | liter | 60 |

| Coolant Tank | liter | 260 |

| Other | ||

| Net/Gross Weight | kg | 5500/6200 |

| Machine Size (LxWxH) | mm | 3750x2050x2250 |

Application